Dental Lab Services Designed for Dental Professionals

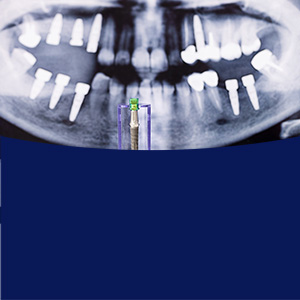

For many years, the picture of a dental laboratory was one of handbook craftsmanship—artisans carefully sculpting crowns and links by hand. As the beauty remains, the equipment have changed dramatically. Nowadays, the dental lab market is starting an electronic digital revolution that's reshaping restorative dentistry, making techniques quicker, more exact, and aesthetically superior.

That shift isn't almost comfort; it's about patient outcomes. New market reports show a rise in the adoption of electronic workflows, with a substantial proportion of labs today applying Computer-Aided Style and Computer-Aided Manufacturing (CAD/CAM). That engineering makes for the generation of restorations with micron-level precision, reducing the requirement for changes and ensuring an improved fit from the start.

The Increase of Digital Thoughts

Removed are the times of messy, uneasy alginate impressions that always induced a patient's gag reflex. The development is moving fast toward intraoral scanning. Statistics show that the marketplace for intraoral scanners keeps growing significantly, driven by the need for individual ease and scientific efficiency.

Digital impressions give quick feedback. A dentist can see the planning on a display in real-time, repairing errors ahead of the file is even provided for the lab. That streamlined conversation involving the clinic and the research decreases turnaround times significantly. In place of waiting weeks for a crown, people can usually have their permanent restorations placed much sooner.

3D Making: Beyond Prototyping

While milling is a addition of digital dentistry for some time, 3D printing is the brand new frontier. It is no more just for designs; laboratories are actually making medical instructions, splints, and even denture bottoms with extraordinary pace and accuracy. The efficiency of additive production indicates less product spend compared to subtractive milling methods.

That engineering enables dental experts to handle complex geometries which were previously hard or difficult to achieve by hand. The end result is an amount of modification that really mimics organic dentition.

Material Creativity

Engineering isn't pretty much hardware; it's in what we place in the mouth. The development of new products, such as for example high-translucency zirconia and advanced ceramics, is a huge game-changer. These components provide the strength required for posterior teeth while providing the cosmetic features needed for anterior restorations.

The information implies a powerful change from metal-based restorations toward these monolithic, metal-free options. That development is driven by patient demand for natural-looking laughs and the biocompatibility of the modern materials.

Looking Ahead

The integration of synthetic intelligence (AI) in style computer software is another big wave. AI calculations are beginning to aid technicians in planning caps and bridges by proposing excellent shapes centered on thousands of effective cases. That symbiosis of individual knowledge and machine learning promises to raise the conventional of attention actually further.

As dental lab engineering continues to improve, the distance between the dental chair and the laboratory counter narrows. For dental specialists, keeping abreast of the tendencies is no longer optional—it's needed for providing the high-quality attention that contemporary people expect.

Can be your practice willing to grasp the electronic potential? Exploring these technical developments may start new gates for efficiency and patient satisfaction in your restorative work.